Straw pre-treatment equipment

Straw pretreatment system process description

Raw material description: cotton stalks, straw, round bale, square bale, bulk, moisture content ≤ 20%.

1.Process design program:

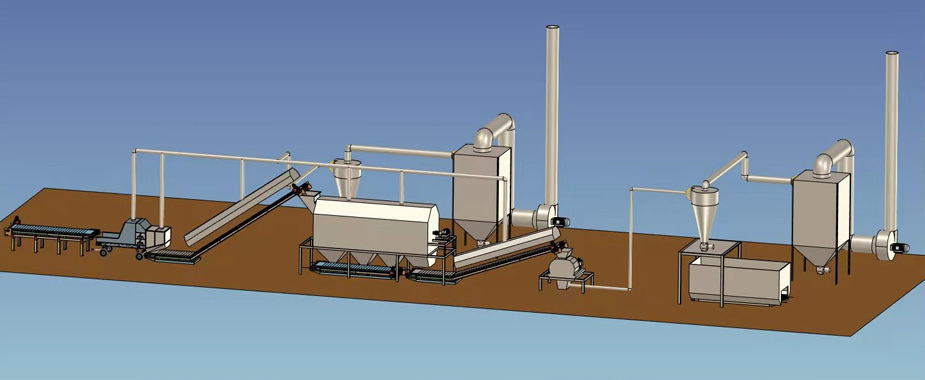

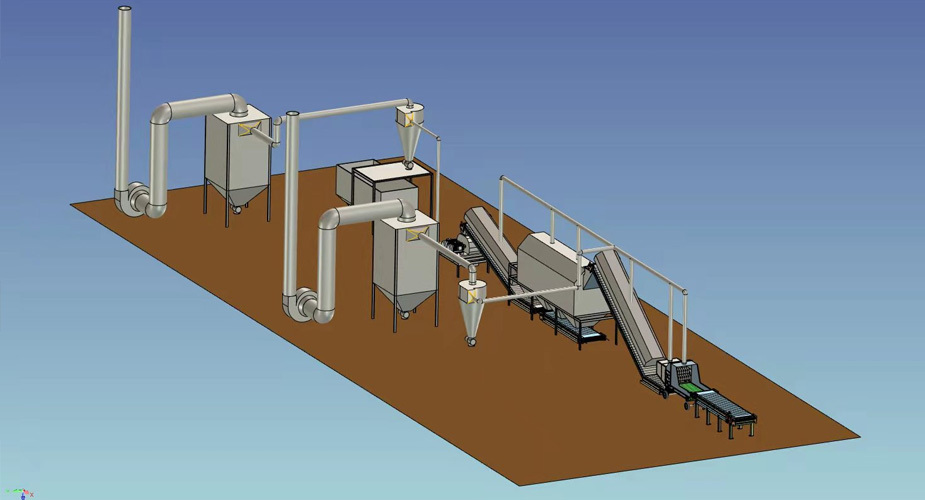

The whole system is divided into: unrope (unbale) section - bale breaking section - dust removal section - cleaning section - dust removal section - (crushing section) - finished material collection and dust removal section.

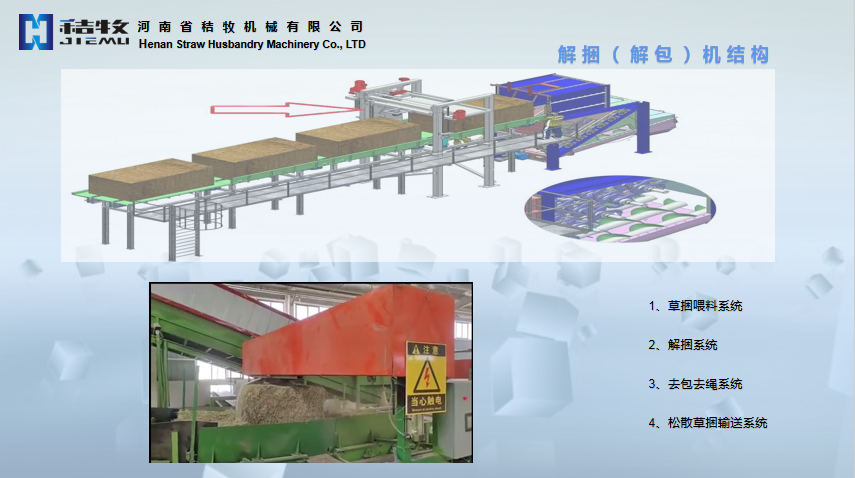

(1) Unstringing (Unbundling) section: Bundle loaded straw (small square bale, big square bale, second pressurized square bale, garden bale), firstly, put the bale onto the plate chain conveyor platform by grass catcher, and then conveyed to the unstringing mechanism through the No.1 plate chain conveyor inverter to cut out the tying ropes and nylon mesh rope, and the ropes will be collected through bypass road.

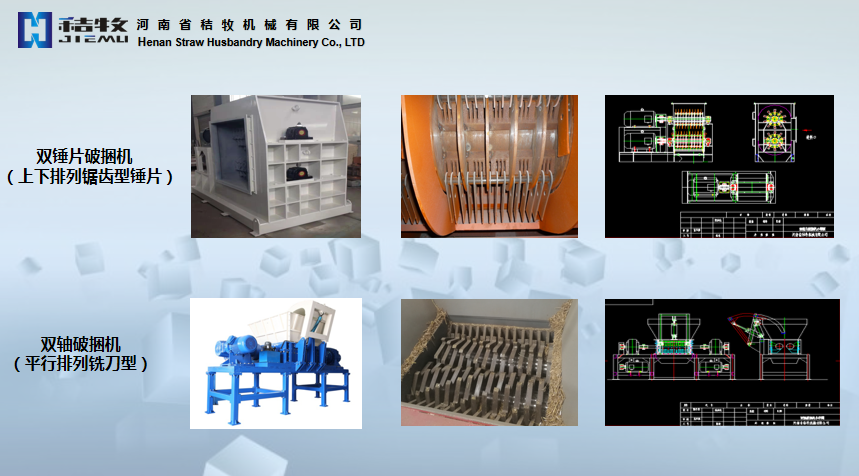

(2)The bundle loaded straw with the rope cut out enters into the bale breaker, the bale breaker breaks the straw to the strength of 30-40mm, and sends it to the next section by the No.2 plate chain conveyor, the circuit design adopts the inverter motor, and the top of the No.1 plate chain conveyor is docked to the centralized dust removing wind screen by installing the sealing leather curtain.

(3) Unbundling and bale-breaking section of the dust removal system: before and after the unbundling of the No. 1 plate chain conveyor and bale-breaking crusher before the plate chain conveyor and bale-breaking crusher above the installation of dust sealing curtains, through the introduction of centralized dust removal system through the dust removal wind network, the centralized dust removal system adopts the combination of fan unloaders - shutter - secondary unloaders - shutter - pulse dust collectors - shutter - dust chimney to achieve the workshop dust-free, and the dust chimney 15 meters high, with a high dust level. Dust chimney 15 meters high spiral galvanized pipe, motor with explosion-proof function, set the fire hazard alarm function to achieve the indoor dust concentration of less than 10mg/m3, outdoor dust concentration of less than 150mg/m3.

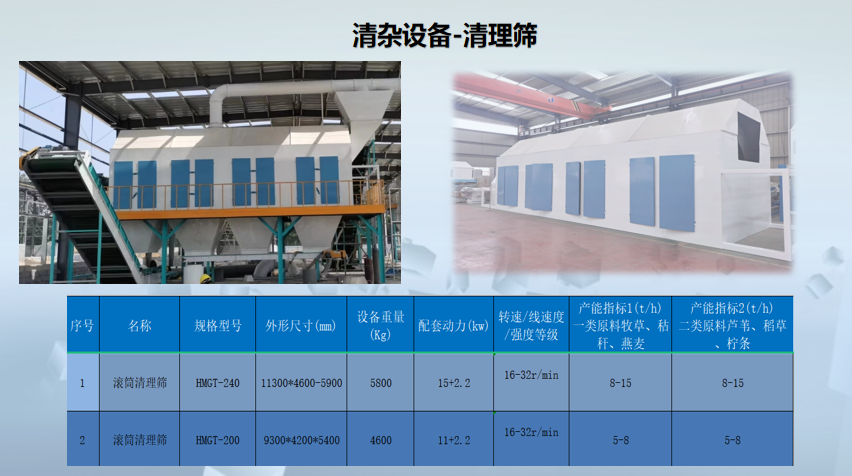

(4) Screening and cleaning section: Straw segments are transported to the screening and cleaning section through No.2 plate chain conveyor. There are mainly straw cleaning screen, fan, pulse dust collector, air closure, No. 3 plate chain conveyor, permanent magnetic self-unloading iron remover and other equipment. Crushed straw segments in the first after breaking the bundle through the permanent magnetic self-unloading iron remover to remove ferrous materials, the use of high-strength rare earth neodymium iron boron magnetic core, with a strong magnetic field, high magnetic field gradient, conveyor belt conveying iron, can realize continuous suction and abandonment of the iron, the belt has an automatic corrective function, reliable operation, maintenance is simple, and its internal magnetic circuit adopts the perfect magnetic pole structure, to ensure that the whole machine in the harsh environment trouble-free long-term operation, explosion-proof, the magnetic plate, the magnetic plate, the magnetic plate, the magnetic plate and other equipment, and so on. Operation, explosion-proof type, magnetic plate strength 150MT, clean up 0.1-30kg ferromagnetic material. 2 plate chain conveyor sends the straw segments into the straw cleanup sieve, 4 different sieve mesh working surfaces are set up in the cleanup sieve, the materials entering the roller sieve go to different trajectories through different specific gravity, and go to the exit corresponding to different sieve mesh through different external dimensions, so that the straw can be cleaned up from the dust, fine gravel and sand. Auxiliary dust removal equipment system can deal with the dust generated in the screening process. Fans, pulse dust collectors, and air closers form an effective dust removal wind network.

(5) Dust removal system in the clearing section: dust sealing skin curtains are set above the iron remover and No.2 plate chain conveyor and above the cleaning sieve and above the cleaned No.3 plate chain conveyor and the temporary storage bin of the grass section, which are introduced into the centralized dust removal system through the dust removal wind net, and the centralized dust removal system adopts a combination of fan unloader - wind closure - second stage unloader - wind closure - pulse dust catcher - wind closure - dust removal chimney to realize the workshop No dust, dust chimney 15 meters high spiral galvanized pipe, motor with explosion-proof function, set the fire alarm function, to achieve indoor dust concentration of less than 10mg/m3, outdoor dust concentration of less than 150mg/m3.

(6) fine crushing section: equipment configuration: the main frequency converter plate chain belt conveyor - double rotor mill - fan - 1 stage duplex unloader - shutter - 2 stage unloader - shutter - pulse dust collector - shutter - dust chimney - grass powder discharger and other equipment.

2.Process description:

No.4 plate chain conveyor will feed the cleaned straw into the straw pulverizer, according to the change of current of the pulverizer automatically adjust the feeding speed of the plate chain belt conveyor to ensure that the pulverizer is fully loaded, according to the fineness requirement of straw pulverization, it can be configured with different sieve boards to process different fineness of straw powder. Generally, there are various kinds of sieve boards from 2mm to 30mm.

The finished straw powder after crushing is transported to the next section by the joint action of wind 1-stage duplex unloader - wind shutter - 2-stage unloader - wind shutter - pulse dust collector - wind shutter - dust chimney - straw powder discharger.

3.System safety design program:

(1) Workshop dust and explosion-proof safety management measures

Fiber raw material pretreatment, fiber raw material temporary storage and transportation, etc. is an important dust and explosion-proof prevention and control areas, dust control and explosion-proof control is particularly important, in order to ensure the safe operation of the complete set of systems. The feeding and discharging ports of the key links take the combination of fan - unloader - dust collector - chimney to realize the workshop dust-free, with explosion-proof motors, and set up the alarm amount of fire hazard prompting function.

(2)Three wastes management

According to the production characteristics of the workshop, the workshop production process does not produce waste gas, waste water, but there are dust and noise hazards, in order to ensure that the health of workers and the surrounding environment is not contaminated, the design according to the relevant norms, to take a single dust collector, more than one set of dust collection points, isolation of the main sources of noise, to be a comprehensive treatment. Noise management of the workshop is the main source of noise crusher, fan, compressor, particles of raw materials and the wall of the collision of the noise generated by the design of the following measures to ensure that the noise ≤ 85dB (A), the crusher, the fan is equipped with silencers, the crusher is set up to isolate the room, the crusher soft start.

Dust treatment.

① in the raw material feeding port are equipped with suction dust collector, dust chimney {15 m high spiral galvanized pipe).

② the entire system in the operation process to ensure that as far as possible in the negative pressure work, that is, can set up a single suction dust removal place, the use of stand-alone suction dust removal, and other parts of the air with dust suction mesh, dusty air in the discharge of the air before the filtration of the pulse bag filter to ensure that the indoor dust concentration of less than 10mg/m3, outdoor dust concentration of less than 150mg/m3.

③Strengthen the sealing performance of the equipment.

(3) Labor protection

①Take measures mainly for sealing and dust removal for dust source to effectively reduce the concentration of dust in the warehouse, which is lower than the explosion point.

② In the staff operation and maintenance parts, are set up platforms, railings, warning signs.

③Electrostatic grounding to prevent sparks.

④ High degree of automation, greatly improve the operating conditions of production workers, reduce the labor intensity of workers.

4. Complete set of equipment operation guarantee system:

The straw pretreatment system to develop training lesson plans: sub-management regulations, operating procedures, maintenance and maintenance procedures, equipment, general troubleshooting procedures, equipment in the medium and long term intact state of the assessment criteria, the organization of operators and management personnel training exams, the examination of those who passed the examination issued by the on-the-job operating certificate.

I. Sub-management regulations; each section, each position clear operators, managers, job responsibilities include: daily inspection content and regular inspection content, daily inspection content will be based on the characteristics of the equipment to develop the inspection content, such as crusher time point bearing temperature rise, crusher noise, crushing the crushing rate of raw materials, and so on.

II. Operating procedures: including safety regulations, inspection before start-up, start-up sequence, shutdown, shutdown sequence, inspection after shutdown and so on.

Three. Maintenance and maintenance procedures: in accordance with the heavy maintenance, light maintenance, to achieve the overall goal of priority plan downtime, for different equipment for their own characteristics of the development of detailed maintenance and maintenance plan, each equipment maintenance time, grease type, maintenance responsibility, maintenance supervisor, the normal maintenance process illustrated.

5. Equipment troubleshooting knowledge and emergency plans:

Each piece of equipment has a catalog of possible failures and corresponding solutions, in the event of a problem can not be solved in one hour emergency program, including control system bypass conversion, the timely availability of standby machines, accessories to set up an alarm line and so on.

6. Evaluation of equipment for mid- and long-term intactness:

Based on industry specifications and equipment configurations of the complete system. The age of equipment use, determine the regular time and assessment criteria. Determine whether the equipment into the technical state, mainly in accordance with the technical principles of can continue to work; should continue to work should not be the principle of operational safety and the suitability of unsuitable to continue to work. Due to the sharp increase in the degree of wear and tear of the equipment, and the equipment failure rate increases, which leads to equipment failure downtime is too much, can not work properly or working time can not be guaranteed.

7. Establish a file for the straw pretreatment equipment:

The file consists of an equipment ledger, individual equipment file, general parts file, parts inventory plan, parts inventory record, and ring mold file. Equipment ledger one page for each piece of equipment, summarized in a book.

1、Equipment ledger

First established by the Ministry of Engineering, two copies, one of which should be transferred to the branch of the new plant or lease transformation of the old plant transferred to the branch of the Ministry of Production, the other one by the Ministry of Engineering custody; branch of the Ministry of Production to receive the equipment ledger with the workshop equipment and peripheral equipment to be compared to be sure of the accuracy into the file to be saved; in the operation of equipment, such as the equipment carried out by the technological transformation or replacement, should be made to the equipment ledger Corrections should be made to the equipment account.

The equipment account of each branch is kept in the office of the production department.

2、Single equipment files

Established by the production department within six months after receiving the workshop. One of the equipment ledger is a copy of the total equipment ledger in the equipment page; special content according to the actual situation of the equipment and equipment ledger together with the record into the file; non-standard accessories specifications and drawings should be in the accessories of a maintenance or replacement of the mapping and into the file; equipment manuals are missing should be obtained as soon as possible to the manufacturer or to the sister company to find the same model equipment manuals to produce a copy of the record should be made in each maintenance records. Maintenance records should be filled in each maintenance completed maintenance card into the file; the rest of the content according to the actual situation of the equipment to supplement.

Individual equipment files are kept in the office of the production department.

3、General parts file

Received by the production department within six months after the establishment of a complete, two copies, one copy of which is kept in the office of the production department, one copy of which is kept in the maintenance room.

4、Accessories inventory plan

By the production department after receiving half a year according to the actual use of the situation, in consultation with the maintenance workers, financial personnel to determine the preset low number of alarm line, timely replenishment, accessories inventory plan in two copies, one copy saved in the office of the Ministry of Production, one copy saved in the accessories library.

8. Remote supervision and guidance systems:

The user and equipment manufacturer to establish a channel for remote assistance, first of all, in the main equipment in the main location of the infrared system, in the use of equipment during the sampling, in the equipment maintenance period of remote inspection, timely correction of erroneous practices, to ensure that the site personnel is in accordance with the operation and maintenance plan done in advance in the work. Ensure the goal of planned downtime.

Straw pretreatment broken bales in addition to weed and iron removal model diagram is as follows:

Cotton straw cotton ball cleaning machine

Cotton straw mixed with cotton peaches and cotton balls, in the crushing and cleaning process, due to the floating nature of cotton balls, combustibility, easy to cause air pollution, and fire risk, clogging cleaning equipment screens, the development of the cotton ball cleaning machine through the wind to clean up the cotton balls, to solve the problem of poor working conditions, and at the same time, cotton balls as raw materials for forage into the forage mixing section.