Steam-exploded fermented forage

Straw and shrub broken wall “nitrogen” feed equipment and animal central kitchen equipment technology

This technology, supported by the Meat Sheep Industry Technology System, is a feed utilization technology for straw and shrubs developed to solve the dual problems of high cost of concentrate and shortage of good roughage, in response to the need of ruminants for good roughage and concentrate supplements, and adopts a feed utilization technology model based on the geopolitical feedstuffs-agricultural and by-products and shrubs, especially straws. This technology produces full-value mixed feeds from agricultural by-products and shrubs through a series of processing techniques such as ripening, wall-breaking and “nitrogen addition” according to their characteristics. One of the core technology links is the roughage wall-breaking “plus nitrogen” process, mainly through the steam blasting of raw materials, high-temperature water vapor cooking fiber raw materials under high-pressure conditions, and through the instantaneous pressure relief process to achieve the separation of raw materials and structural changes in the component, steam blasting process, high-pressure hot steam into the fiber raw materials and penetrate into the internal voids of the fiber. Internal voids, due to the combined effect of water vapor and heat to produce fiber raw materials and thermal degradation of acid-like degradation, dissolution of low molecular substances, fiber polymerization decreased. In the high-pressure steam release, has penetrated into the fiber internal hot steam molecules in the form of airflow from the relatively closed pore high-speed instantaneous release of the fiber inside and around the high-speed instantaneous flow of hot steam, so that the fibers occur to a certain degree of mechanical fracture, which breaks the straw raw materials in the lignin, cellulose, hemicellulose entangled with each other, so as to achieve the use of straw feed, turning waste into treasure. The appearance of the feed is silky, burnt flavor, good palatability, production of a wide range of raw materials, covering almost all kinds of crop residues, such as: corn, rice, wheat, sorghum, grain, oats, barley, soybeans, peanuts, rape, cotton, etc.; twigs, lemon strips, reeds, salal, etc., can also be used for the production of straw shrubs, broken wall “nitrogen” Feed. This feed is an excellent forage for cattle, sheep, horses, geese, deer, camels and other herbivorous animals.

1 ton of straw direct combustion can be gas blasting wall 10 tons of straw, 2 tons of straw bush wall-breaking “nitrogen” feed can replace 1 ton of corn.

1. Characteristics of straw and shrubs broken wall “nitrogen” feed

1、Straw and shrub broken “plus nitrogen” feed in the production process by high temperature steam elimination, no pesticides, fertilizers, herbicides residues, to meet the standards, is a real green forage.

2. Straw and shrub broken “nitrogen” feed is a kind of roughage, but the nutritional value is close to that of concentrate feed. The nutritional value of each kilogram of straw and shrub broken “nitrogen” feed is equivalent to 0.6-0.7 kg of corn. The net milk yield of corn is 1.83 Mcal/kg, and the net milk yield of straw and shrub broken “nitrogen” feed produced by corn or rice straw is as high as 1.72 Mcal/kg and 1.78 Mcal/kg, while the net milk yield of alfalfa is only 1.24 Mcal/kg.

3. Straw and shrub broken “nitrogen” feeds can be used in high-yield dairy farming to solve the problem of imbalance in the ratio of concentrate to roughage in the diet, to ensure the health of dairy cows, and to increase the yields of dairy cows. Used in low and medium yield dairy farming, it can reduce the amount of concentrate feed, reduce the cost of farming and improve the milk fat rate while ensuring the yield of dairy cows.

4, straw shrub broken “plus nitrogen” feed is a cooked and expanded feed, much better than extruded puffed, cattle and sheep digestion and absorption rate of up to 70%. With straw and shrub broken “nitrogen” feed as the main feed for raising cows in the feces, almost can not be seen in the feces of conventional dairy cows in the plant fiber.

5. Straw and shrub broken “nitrogen” feed is produced on an industrial scale, with stable and reliable quality, which ensures year-round supply. Farming enterprises do not need to hoard, easy to buy, less capital. On the other hand, most of the common forage needs to be dried manually, which is seasonal and cannot guarantee stable supply.

6, straw and shrub broken “nitrogen” feed is a real green forage, can be used for the development of ecological farming, the production of beef and mutton, resulting in higher economic benefits;.

The non-fiber carbohydrate content of straw and shrub broken “nitrogen” feed is as high as 30-40%, which is suitable for the production of nutritionally balanced full-value fermented feed, which is the development direction of ruminant feed products, and it can reduce the cost of breeding and improve the breeding efficiency.

2. The production process of straw shrubs and nitrogen added feeds

1、Pre-processing: open the bale, remove the dirt, soil, stone, metal and other debris, crushed and kneaded.

2, hydrolysis elimination: the pre-treatment of broken straw pressed into the steam explosion tank, according to specific parameters into the high-temperature and high-pressure steam, so that the fibers in the straw to soften, decomposition of pesticide residues.

3, steam explosion: instantly open the steam explosion tank release port, high-pressure steam expansion work, the straw from the internal bursting and tearing, the production of straw bush broken “nitrogen” feed is collected in the aggregate tank.

4、Packing and sealing: the straw and shrubs in the aggregate tank will be compacted and packed and sealed, and can be fed or sold directly.

5、Adding auxiliary materials and enzyme preparation: take the straw and shrub wall-breaking “nitrogen-added” feed as the main material, add auxiliary materials and enzyme preparation according to the need, and mix well.

6、Fermentation:the straw and shrub broken wall “nitrogen” feed added with auxiliary materials and enzyme preparation is compacted, packed and sealed, and then stored and fermented at suitable temperature, the finished product is full-value straw and shrub broken wall “nitrogen” feed fermented feed.

3.Storage and shelf life

It can be fed directly, if large farms can be sealed cellar, can be compressed and sealed into large bales for storage, the storage time can be more than 2 years.

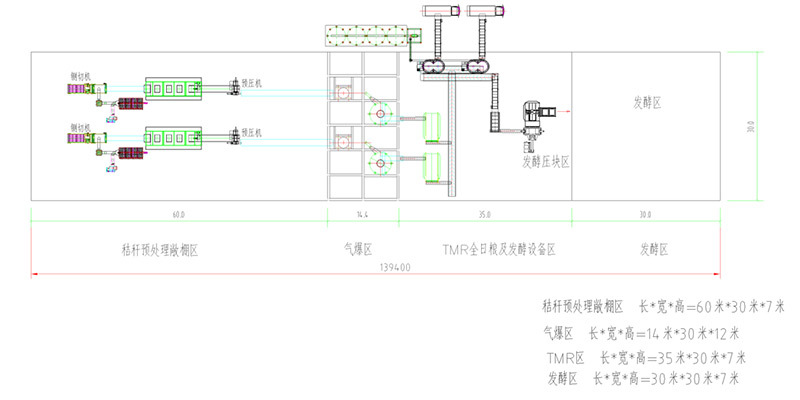

4.Shuozhou annual output of 60,000 tons of straw broken wall fermented feed equipment layout plan

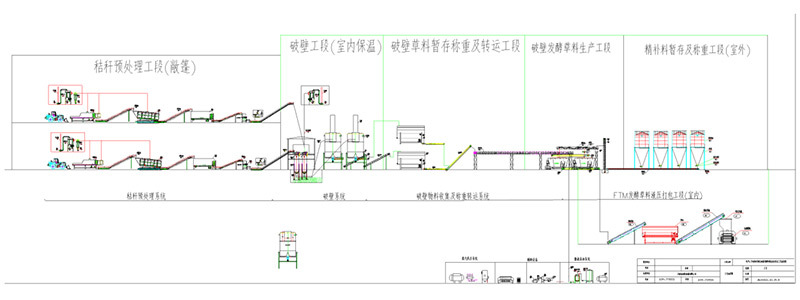

5.The annual output of 60,000 tons of straw broken fermented feed sets of equipment process flow diagram

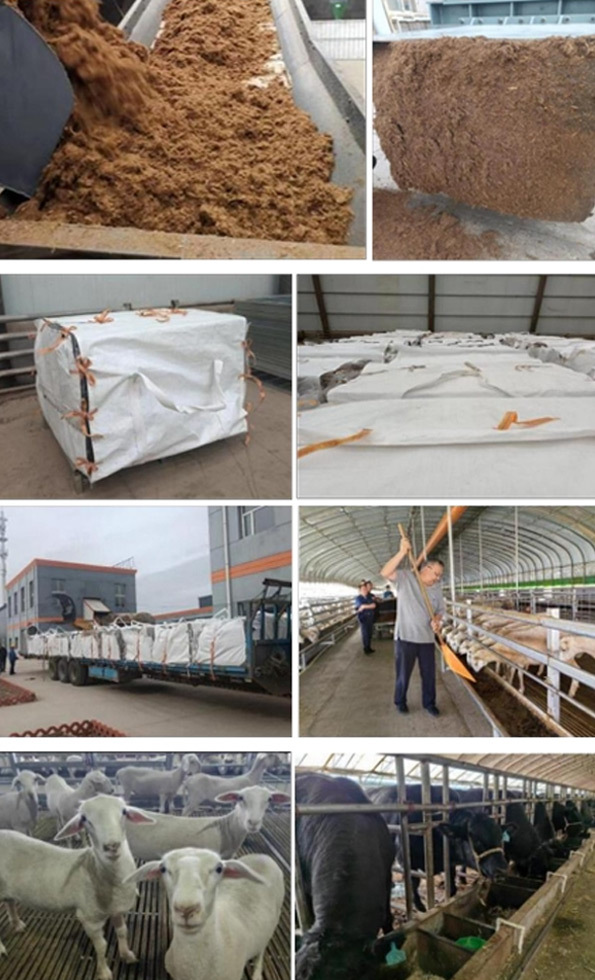

6. Selected site photographs