Animal Central Kitchen

Intelligent “Farm Central Kitchen” is briefly described:

Farm central kitchen project is a feeding technology from the perspective of nutrition, according to the nutritional needs of different stages of growth and development and production, the roughage, concentrate feed, microelements and vitamins needed by the animals are mixed into a nutritionally balanced diet according to the appropriate ratio.

At present, the traditional feeding modes in China are traction mode, self-propelled mode and mixing station mode, which need to be added one by one and each kind needs to be weighed, thus prolonging the feeding time. The precision of dosing is limited. The central kitchen mode of the ranch will add a variety of feeds to the TMR mixing silo at the same time, and each raw material is weighed before entering the TMR machine. Through the feeding management system and centralized control system of the TMRwach, it adopts the functional modularized design scheme, and realizes the seamless connection of internal information of the ranch through the intelligent control system with PLC and data collection and monitoring, and the working scene of the equipments and the data are transmitted to the intelligent cloud platform in a timely manner. Data is timely transmitted to the intelligent cloud platform central control room operation, while the analysis from the dietary formula production, overall feeding curve graph, feeding uniformity curve graph and feeding and discharging error rate trend chart, etc., to help ranch managers to do a good job of grass-roots level data statistics, implementation report, the next step in the data prediction, feed inventory management, as well as the impact of the various aspects of the production of a good data analysis. The process of digital feedback to the ranch intelligent Internet of things, is to realize the important board of intelligent ranch.

1. Comparison of production efficiency, in the case of excluding the spreading time, traction feeding mode production takes 30 minutes, self-propelled mode takes 25 minutes, mixing station mode takes 27 minutes, ranch central kitchen mode in the case of including the time of the feed, the entire processing process only takes 15 minutes, time savings of 15 minutes, efficiency increased by 50%.

2. Comparison of feed accuracy, the traditional mixing station mode generally use manual feeding, the error is generally controlled within 5%, the ranch central kitchen mode, according to the formula of automatic batching, weighing, feeding, greatly reducing the probability of errors and mistakes caused by personnel, the error can be controlled within 1% on average.

3. Comparison of labor: the traditional mode of 10,000 head of cattle farm production board post ideally requires a total of 18 laborers in three shifts, the ranch central kitchen mode only uses 7 people.

4. Comparison of production costs: traditional TMR mixing plant mode, traction mode, etc., per ton of feed processing costs are in the 20-30 yuan, the ranch central kitchen mode processing per ton of TMR feed energy cost of 5.7 yuan (5.7 yuan = electricity costs 4.26 yuan + shovel to the roughage silo refilling energy consumption of 1.44 yuan)

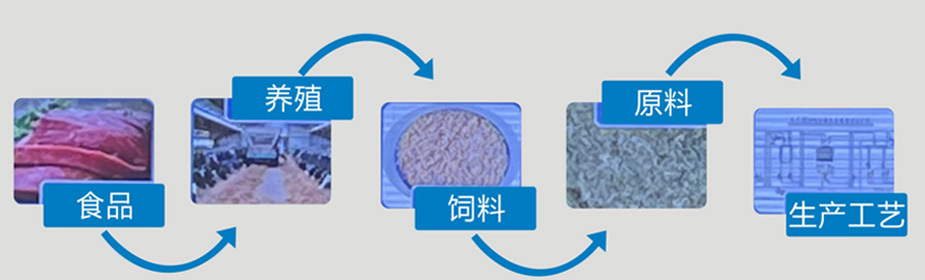

The central kitchen of the ranch is an intelligent feeding distribution center upgraded from the traditional feeding mode, which provides a guarantee system of forage plate for the development of intelligent ranch, and is an important link to guarantee the traceability of food safety.

Introduction to the intelligent “Central Kitchen for Pasture” section:

In order to achieve the overall goal of forage safety and intelligent production, the process of the complete system is divided into 11 sections. Each section has a rational layout, coordinated configuration and continuous operation, which is controlled by TMRwach's integrated feeding management system and centralized control system.

(1) Raw grain cleaning and temporary storage section

(2) Corn crushing and corn meal storage section

(3) Protein material cleaning and storage section

(4) Concentrate supplement temporary storage section

(5) Roughage pre-treatment section

(6) Roughage weighing and adding section

(7) TMR whole diet production section

(8) Liquid weighing and adding section

(9)System safety design system

(10)TMR wach feeding software

(11)TMRwach feeding monitoring system

Centralized control and feeding management system:

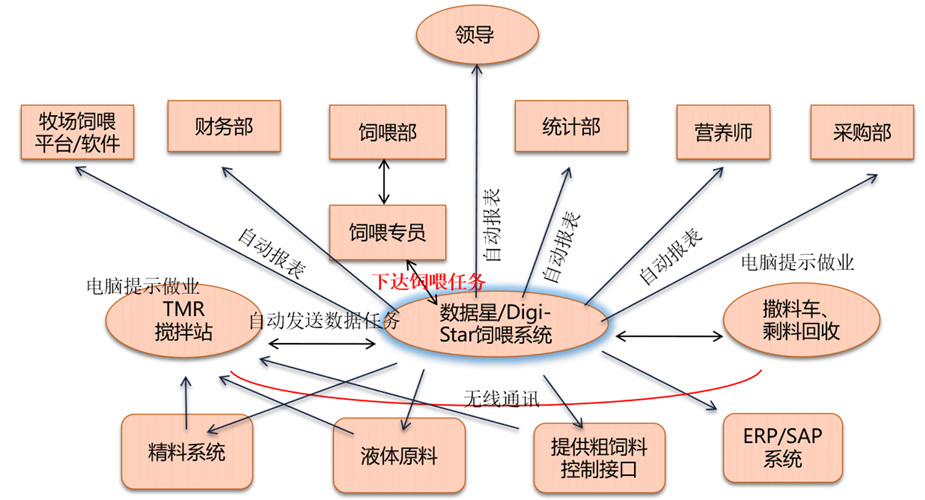

Research and development of DIGI-STAR's feeding management system and centralized control system, this program adopts the functional modular design scheme, which is an intelligent control system based on PLC and SCADS (SupervioryCtontrol And Data Acquisition And Data Acquisition/ Data Acquisition And Monitoring), and realizes seamless connection of internal information of the ranch. Functional modules are divided into: TMR Tracker feeding software module, to achieve the production of feeding formulas, feeding data sending and receiving, the processing of tables and reports, etc.; TMR diet production module, to achieve the addition of materials, multi-stage speed TMR mixing control, diet feeding, roughage processing module, to achieve the roughage according to the requirements of the recipe for a variety of roughage to be added; data transmission module to achieve the automatic data transmission and processing of the rations system and the concentrate system. The data transmission module realizes automatic data transmission and processing of the ration making system and concentrate system, and data docking with the third party software, etc. The working scenes and data of the equipment are timely transmitted to the central control room of the intelligent cloud platform for operation.

Design Program:

The centralized control system serves as the core of the whole feeding station system for centralized data processing and task allocation. Roughage adding tips, concentrate feed automatic control system and feeding management system are integrated by the industrial control system for the control part and operated on the same control platform. The control process is as follows:

(1) Production of TMR diets: TMR Tracker feeding software is responsible for the production of formulas and sends the formulas of different sections to different control systems through network or wireless, and collects information of various diets self-made and generates various data reports, which contain various reports on the degree of operation of the person who produces and spreads the diets, the feeding situation, the amount of dry matter fed, and the consumption of raw materials, etc., and can be used to make reports output according to the requirements. It can also output the reports according to the requirements.

(2) Concentrate making and adding: The concentrate PLC control system collects the concentrate formula data from the feeding system TMR Tracker feeding management software and realizes direct data transmission. The concentrate PLC system makes concentrate and conveys it to the corresponding position according to the formula requirements and automatically controls the adding process of concentrate.

(3) Roughage Conveyor Addition: The roughage formula data of the feeding system TMR Tracker feeding management software, the feeding system processes the data of each roughage formula and displays it on the display screen of each mixer truck, prompting the forklift driver to add it to the corresponding TMR preparation machine in accordance with the adding order and weight in turn.

TMR feeding monitoring system:

TMRwach feeding monitoring system to realize the chemical feeding TMR whole mixed diet monitoring system will shovel truck, TMR, computer system through the wireless equipment linked together, the display can be synchronized to show the TMR loading weight, prompting the operator to carry out business operations according to the plan, real-time reminders to the operator of the amount of each kind of feed dosing or feeding volume,.

Composition of TMR feeding monitoring system TMR monitoring system has main controller, auxiliary controller and software system, the main controller is installed in the TMR car connected with the TMR car load cell, which can receive real-time TMR car weight data. Auxiliary controller is installed in the forklift, feeding point and other feeding position, prompting the completion of feeding, the main controller and auxiliary controller through wireless communication technology for data exchange content synchronization display, a main controller can take more than one auxiliary controller. Installation position of different TMR operation modes:

1、Fixed TMR car, conveyor feeding. Configuration of a TMR monitoring system has a main controller installed in the TMR car or nearby, easy to feed the personnel to view the value can be, feeding and mixing finished discharging TMR monitoring system has a main controller can monitor

2 mobile TMR truck, forklift feeding, and feeding point feeding configuration of a TMR monitoring system has a main controller installed in the TMR cab, an auxiliary controller installed in the cab of the forklift, an auxiliary controller installed in the feeding point.

Feeding management system and centralized control system (PLC modular control):

(c) A system for ensuring the operation of complete sets of equipment:

First of all, the “central kitchen” system to develop training programs: management regulations, operating procedures, maintenance and maintenance procedures, general troubleshooting procedures, equipment, equipment, medium- and long-term intact state of the assessment criteria, the organization of operators and managers training exams, the examination of those who have passed the issue of operating permits for the post.

(1)Sub-management regulations, each section, each post clear operators, managers, job responsibilities include: daily inspection and regular inspection content, daily inspection content will be based on the characteristics of the equipment to develop the inspection content, such as crusher time point bearing temperature rise, crusher noise, crushing the crushing rate of raw materials, and so on.

(2) operating procedures: including safety regulations, check before starting, start-up sequence, shutdown, shutdown sequence, check the content after shutdown.

(3) maintenance and maintenance procedures: in accordance with the heavy maintenance, light maintenance, to achieve the overall goal of the priority plan downtime, for different equipment for their own characteristics of the development of detailed maintenance and maintenance plan, each equipment maintenance time, grease type, maintenance responsibility, maintenance supervisor, the normal maintenance process illustrated.

(4) equipment troubleshooting knowledge and emergency plans: each device is likely to have a catalog of faults and corresponding solutions, in the event of problems can not be solved in an hour should be an emergency program, including the control system bypass conversion, standby in place in a timely manner. Accessories set alarm line, etc.

(5) equipment in the medium and long term intact state of the assessment: according to industry norms and complete sets of equipment configuration of the system. The age of the equipment used to determine the regular time and evaluation criteria

(6). Establishment of central kitchen equipment files, files from the equipment ledger, individual equipment files, general parts files, parts inventory plan, parts inventory records, etc.

(7). Ranch central kitchen” to establish remote supervision and guidance system, the use of the party and the equipment manufacturer to establish a remote assistance channel, first of all, in the main location of the main equipment set up infrared systems, sampling during the use of equipment, remote inspection during equipment maintenance, timely correction of wrong practices, to ensure that the site personnel are in accordance with the operation and maintenance plans made in advance in the work. operation and maintenance plans are working. Ensure the goal of planned downtime.

Choosing the “Central Kitchen” forage production model ensures the advancement, practicability, reliability and economy of the forage processing project, which occupies the high point in the regional industry and has the value of promotion and demonstration in the region.

The “Ranch Central Kitchen” is a revolution in ruminant feeding mode.

'Ranch Central Kitchen' is a key to realize intelligent farming, digital farming